Well pipe trench integrated drainage system

The well-pipe-trench integrated drainage system refers to the drainage system that inspection wells, drainage and sewage pipelines, and drainage ditches (rain inlets) are all made of polymer materials, which are uniformly designed by the same manufacturer, uniformly prefabricated and assembled on site.

The system is characterized by fast installation, accurate size adaptation between the components, and truly sealed without leakage.

The components of the system are durable and have the same cycle life. There are quality problems, the main body of responsibility is clear, and the traceability is fast and efficient.

Product Series

The well-pipe-trench integrated drainage system refers to the drainage system that is developed and designed by the same manufacturer, prefabricated and produced in the factory with polymer resin, and assembled on site by inspection wells, drainage and sewage pipes, and drainage ditches (rain gates). The system is characterized by fast installation, accurate size adaptation between the components, and truly sealed without leakage. The components of the system are durable and have the same cycle life. There are quality problems, the main body of responsibility is clear, and the traceability is fast and efficient.

Characteristics of well pipe trench integrated drainage system

Fast construction

All parts of the entire drainage system are made of polymer materials, the selection of injection molding or extrusion process in the factory prefabricated production, in the field can be modular installation, application. The work efficiency is more than 10 times higher than that of the traditional drainage system.

Guarantee duration

All components are designed, produced and sold by the same manufacturer. The size adaptability between well pipe trenches is good, so as to ensure that the matching is completed before leaving the factory, instead of on-site selection and matching work, so as to avoid return and exchange caused by unmatched matching. All parts can be delivered at the same time, at the same time into the construction. Avoid multiple manufacturers to supply, the arrival time is different, affecting the construction period.

Seamless docking of each component to achieve zero leakage

All parts of the system are designed and produced by the same manufacturer. The dimensions of the parts are accurately adapted, the sealing is good, and zero leakage is realized.

Reduced owner costs

1. In the early stage of procurement, the owner only needs to communicate with the same manufacturer at the same time about products, technology, services and business undertakings to reduce communication costs. 2. The comprehensive cost of the system is lower than the traditional process, reducing procurement costs. During the installation process, the owner only needs to carry out technical handover and technical connection with the same manufacturer to reduce communication costs.

Stable and reliable, convenient for construction quality control

The production of all components is governed by a strict quality management system. The size of the components is accurately adapted, the installation process is standardized and simplified, and the system sealing is guaranteed, which is convenient for on-site construction quality control.

The quality responsibility subject is clear

In the process of system installation and operation and maintenance, if there is a product quality problem, the main body of responsibility is clear, all problems are solved by the same manufacturer at the same time, and all responsibilities are borne by the same manufacturer.

Plastic Inspection Well Connection Technology

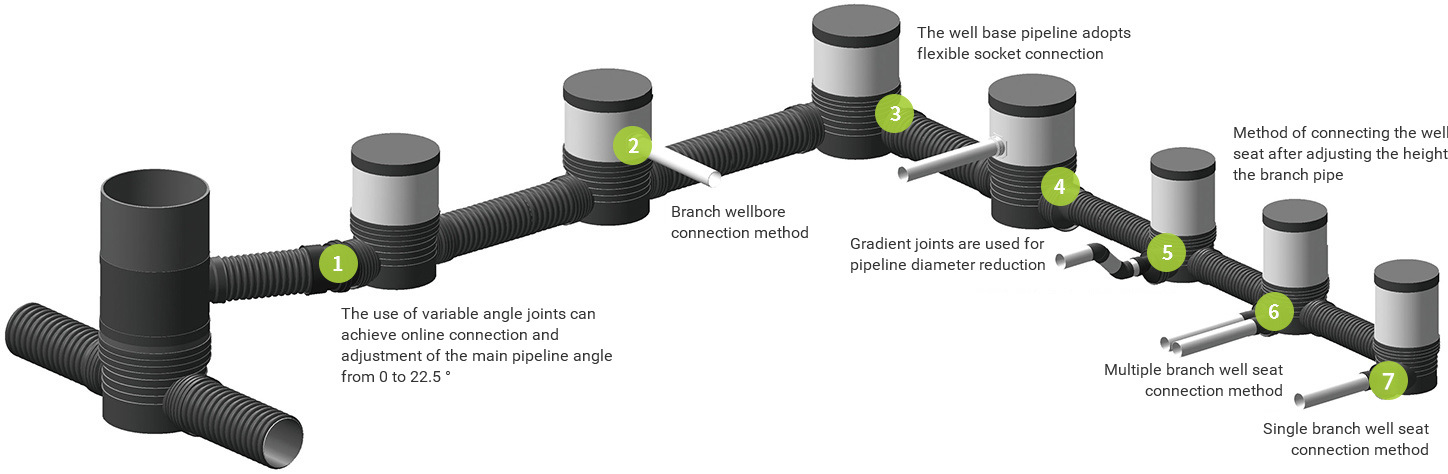

branch pipe connection technology: When the height of the branch pipe is above the well seat, the wellbore access method is adopted; otherwise, the well seat access method is adopted. Hippo well's unique branch pipe connection technology can ensure that multiple branch pipes (PE, PVC pipe, cast iron pipe, galvanized pipe) are sealed and reliably connected with the inspection well from any angle and any height.

Supervisor Connection Technology: Unique can be applied to various types of buried pipeline direct flexible socket connection, and can ensure that the pipeline angle online continuous adjustable. The advantages of flexible socket connection are convenient and reliable installation, good sealing, and can adapt to a certain degree of settlement.

1. The online connection of the main pipe can be adjusted by using the variable angle joint from 0 to 22.5 degrees.

In the process of pipeline construction and installation, the pipeline is not always a straight line or a specific angle. Sometimes we need to adjust the pipeline angle. In this case, 0~22.5 ° variable angle joints can be used for on-site adjustment to facilitate installation and construction and improve work efficiency.

2. Branch pipe wellbore access method

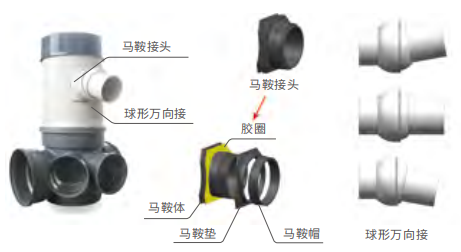

First, use a hole opener to open a hole in the wellbore at the branch pipe access position, then install a saddle joint on the wellbore, and finally connect the branch pipe to the saddle joint.

The components of the saddle joint include: saddle cap, saddle pad, rubber ring and saddle body. Spherical universal joints are often used to adjust the angle and height, easy to install and can adapt to a certain settlement.

3. The well seat pipeline adopts flexible socket connection

The well base can be suitable for direct flexible socket connection with all buried pipelines.

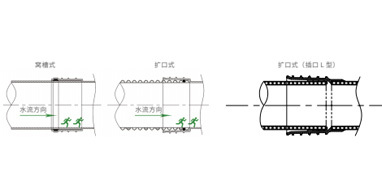

Solid wall pipe or flat wall structure pipe, using flared (socket L-shaped) elastic sealing rubber ring flexible socket connection;

Double-wall corrugated pipe, the use of flared elastic sealing ring socket connection; small diameter solid wall pipe, can also use the socket type sealing rubber ring flexible socket connection.

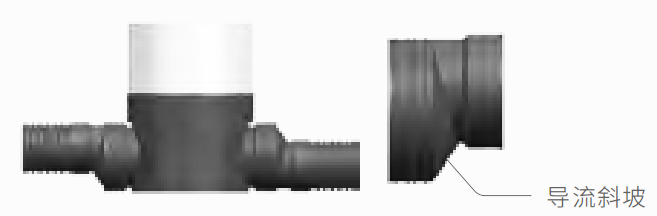

4. Gradient joint is adopted for pipe diameter reduction

The gradient joint should be set with the structure of the diversion slope to avoid the retention of dirt. As the drainage is gravity flow, the structure of the diversion slope can avoid the direct drop of water flow and cause large head loss, so as to avoid the retention of dirt and blockage of the pipeline.

5. Well seat access method after adjusting branch pipe height

When the elevation of the branch pipe cannot be connected from the wellbore opening or directly connected to the well seat, the elbow can be used to adjust the height and connect to the well seat from the middle.

6. Multi-branch pipe well seat access method

When two or more branch pipes are connected to the well seat, it can be used.

Use a junction joint or a special well seat.

7. Single branch pipe well seat access method

When a single branch pipe is connected to the well seat and needs to be changed in diameter, it can be

Use reducer fittings for conversion.