Low carbon water treatment system

Application scope: winery wastewater, domestic sewage, aquaculture wastewater, airport deicing and rainwater runoff, sewage plant tail water standard, river treatment, industrial and mining wastewater, landfill leachate.

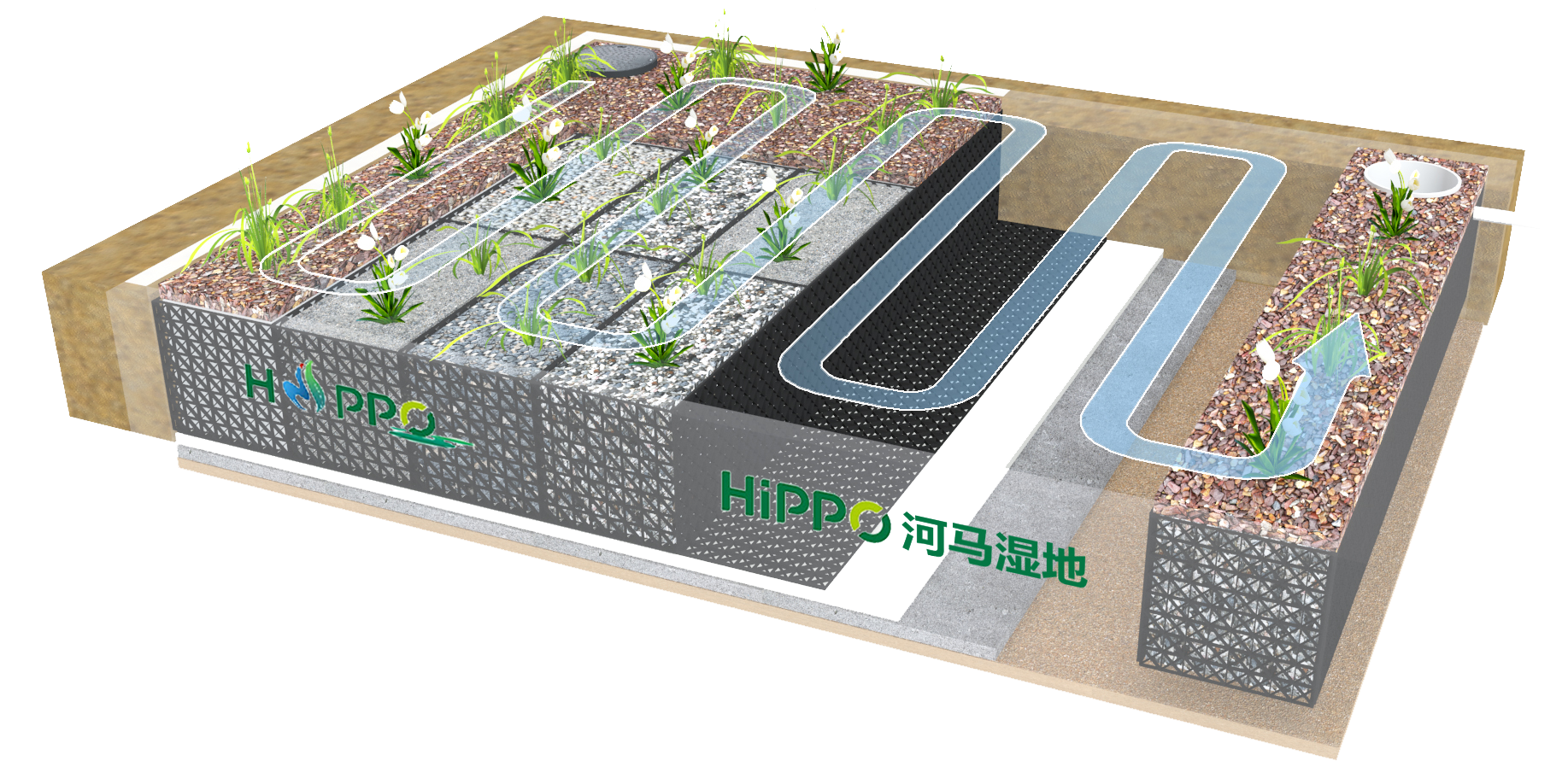

Introduction of Modular Constructed Wetland Technology

[Overview]]The artificial wetland solution is not standardized, and it is necessary to design a more preferred solution for users to choose according to the design intake and measured water quality of the project, combined with the geographical location of the project and the project budget.

advantages]Reduce the wetland area by 1/2-3/5; The combination of engineering products and the reduction of construction period; The life of the wetland has been extended to 10 years. Because the blocked place is seen in the first place, it is extremely convenient to deal with the blocked place.

EA-CWS Modular Constructed Wetland Technology

EA-CWS "Modular High-efficiency Wastewater Treatment Integrated Technology of Constructed Wetland" is EA-CWS for short. Developed by China-Europe Constructed Wetland Technology Research and Development Center, the exquisite artificial wetland technology is an enhanced high-efficiency wastewater treatment wetland developed on the basis of natural wetlands. Through the physical, chemical and biological synergy of substrates, plants and microorganisms, sewage purification is completed, phosphorus and nitrogen removal are enhanced, and both landscape effects are achieved. This technology, combined with local enhancement, increases the processing capacity by more than 15 times. Can handle COD, BOD,SS,NH4-N and other organic pollutants. This is not comparable to conventional wetlands.

EA-CWS, it changes the form of water flooding in conventional wetlands and solves the short-flow phenomenon of conventional wetlands. through hippo constructed wetlands changing to the magic box, it increases the sewage runoff path by 5-10 times, thus enhancing the treatment effect exponentially.

MOYA-CWS sludge treatment wetland technology

On the basis of the existing modular wetland technology (EA-CWS), combined with the technical characteristics of the French vertical flow wetland treatment of direct primary sewage, to create our sludge treatment technology, referred to as MOYA technology.

Constructed wetlands have been used for dewatering of wastewater sludge

Since 1988, Europe has been gradually applying sewage treatment plants. Especially France and England. Sludge dewatering is caused by drainage, evaporation, evapotranspiration and reduction of organic matter (mineralization). At present, the largest sludge treatment wetland has the highest influent of 22,500m 3/D. The treatment system comprises at least eight individual reed wetlands with a depth of 2.0-2.5 meters. The sludge has a dry solids content of 0.5-5% and is sequentially pumped to each wetland to achieve the designed solids load. According to the characteristics of the sludge, the maximum sludge load is 40 - 60 DS /m2/year. After about ten years of operation of the sludge, the residue will reach a height of 1.20-1.50 meters with a dry solids content of 30-40%. The establishment and operation of the system is considered to have less environmental impact than alternative mechanical sludge dewatering systems, which do not require the use of traditional chemicals, incinerators, transportation and disposal. Experience has shown that the pathogen removal rate of harmful organic compounds is very high. The solids formed after sludge mineralization can be recycled to agriculture for reuse as nutrients.

GAIA Constructed Wetland Technology

The GAIA constructed wetland integrates all the green ecological technologies of the China-Europe Constructed Wetland R & D Center, and can treat the ultra-high concentration animal husbandry wastewater. It integrates EA-CWS technology, reciprocating wetland technology, local convenient replacement filler, tidal flow technology and modular aeration technology. GAIA is a hybrid technology that combines anaerobic pretreatment with intensification, is cost-effective and is suitable for users with demanding land areas. Can replace the active electromechanical wastewater treatment system.

GAIA wetland technology has been successfully implemented in several European cities as well as industrial wastewater systems, including pig farms, dairy farms, poultry farms, monasteries, pickling plants and domestic sewage. It has been proved to be effective in the treatment of wastewater containing high concentrations of organic matter and ammonia.

Advantages of low carbon water treatment system

Application scope: winery wastewater, domestic sewage, aquaculture wastewater, airport deicing and rainwater runoff, sewage plant tail water standard, river treatment, industrial and mining wastewater, landfill leachate.

Environmental protection and energy saving

The MOYA system reduces CO2 emissions compared to other dehydration methods.

Environmental protection and energy saving

The use of naturally occurring microbial animals to reduce and treat sludge. The only power consumption comes from the transfer pump and the sprayer in the sludge buffer tank.

Less emissions

The MOYA system reduces CO2 emissions compared to other dehydration methods.

Recycling

After treatment, there are many recycling options, including use as fertilizer on agricultural land. Sludge quality is cleaner and more adapted to the natural cycle of agricultural use than mechanical dewatering of sludge.

No chemicals

No chemicals are used to treat the sludge, reducing potential health and safety issues in the work environment while reducing chemical residues in the treated wastewater.

No smell

Mineralization occurs through aerobic degradation, so the MOYA system has no odor problems.

Improve the environment

The content of substances harmful to the environment can be reduced to the extent that the sludge is compatible, reaching the deposition limit on agricultural land. A 6 log reduction in infectious solids was seen in the residue removed from MOYA.

Reduce cost

The MOYA system will reduce the cost of transportation and paving by more than half, because the volume of sludge can be reduced to about 1/3 of the water mechanically dewatered sludge.